Products

"g" series cartridges for natural gas

These cartridges have been used for about 40 years for the filtration of natural gas and hydrogen in decompression cabins. The standard filtration degree is 5 microns, new studies and tests have allowed us to expand the range with new materials and filtration grades.

The “G” series cartridges are used to filter natural gas and hydrogen in decompression cabins.

The effectiveness and safety of use of these cartridges, their high pleated filtering surface, allows the filtration of all the dust and mechanical particles that come into contact with the filter media.

The standard filtration degree is 5 microns, new studies and tests have allowed us to expand the range with new materials and filtration grades.

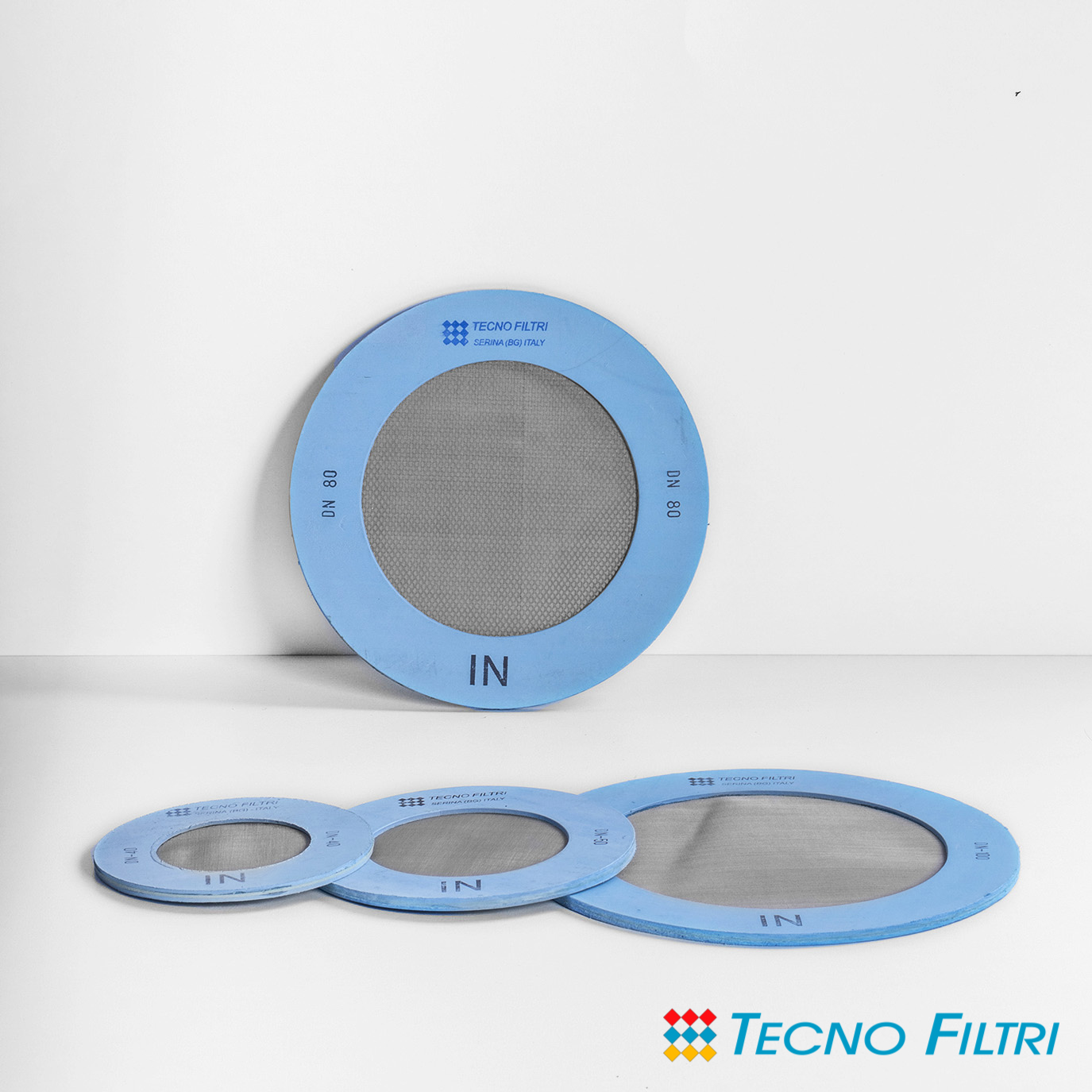

disc filters

In recent years, the advent of new generations of gas meters has made it necessary to create new interflange filters to protect the sensitive parts of the meters (pistons, rotors, etc.). The passage of dirt particles can in fact damage the moving parts and the measuring chambers.

TECNO FILTRI SRL leader in the natural gas filtration sector, has designed and built these interflange discs using suitable materials to create a product of absolute quality able to meet the needs of customers.

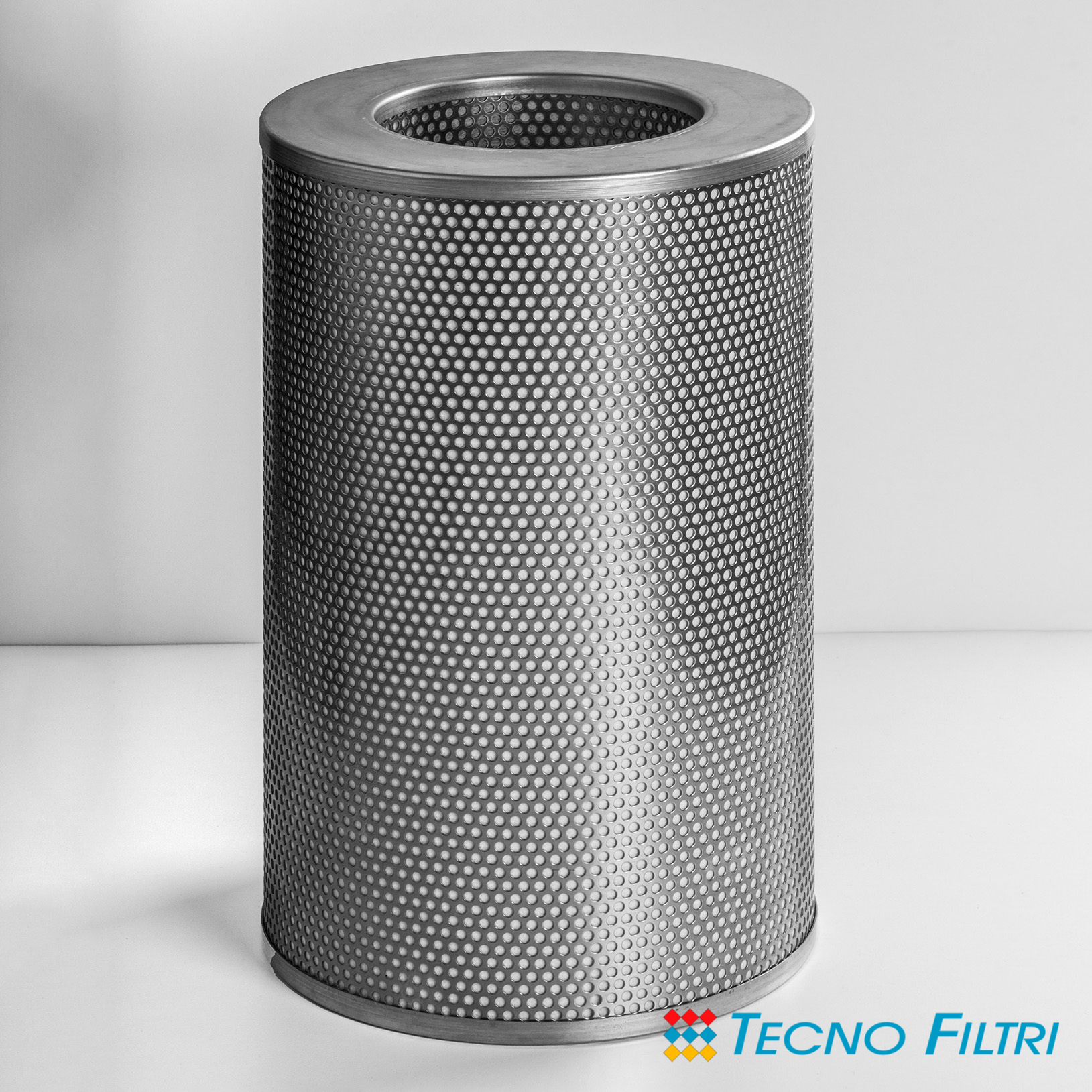

FILTER CARTRIDGES FOR REFINED PETROLEUM PRODUCTS, CHEMICAL SOLVENTS AND SEA WATER

These cartridges have been developed to allow the filtration of solid particles present in petroleum refining derivatives.

They are completely produced in 316L stainless steel and used for amines, fuel oils, alcohols, gasolines and sea water.

COALESCENT FILTER ELEMENTS

Filter elements designed and studied for the removal and separation of contaminants such as: oil, solid particles, and hydrocarbon vapors, present in the air and gas, ensuring a residual vapor up to 0.01 mg / m³.

The continuous search for new filter media has allowed us to optimize our cartridges by giving them a high filtering power capable of retaining impurities down to 0.01 micron.

TFJ COALESCENT FILTER CARTRIDGES

TFJ 536 cartridges are used in the forced filtration of natural gas and air and are responsible for the elimination of solid and liquid particles.

They have a great capacity of accumulation of pollutants and a great resistance to crushing by means of the high resistance internal protection.

The sense of filtration occurs from the outside to the inside and are available with filtering capacities from 1 – 3 – 5 microns.

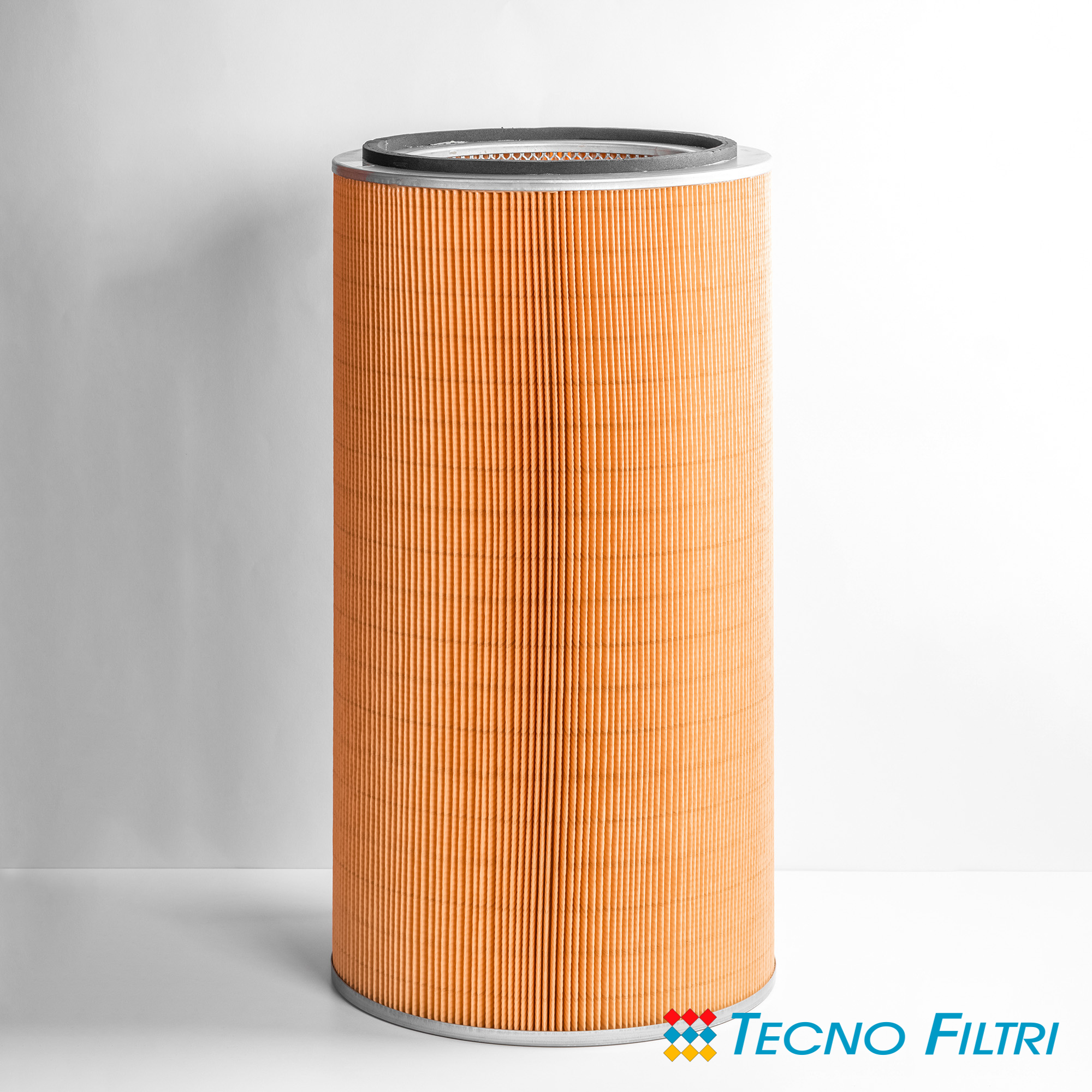

DEDUSTING CARTRIDGES

These filter cartridges are used for the separation of dry impurities suspended in the air and are mainly used in dedusting, but they can also be found in blowers, vacuum pumps and air compressors.

The attention and care in the choice of materials and the high professionalism of the staff make it possible to create high quality filter cartridges.

vpz and zpz series cartridges for biogas

These cartridges were created to meet customer needs for natural gas and biogas filtration. Biogas are a mixture of various types of gases, mainly composed of methane, produced by bacterial fermentation in anaerobic (absence of oxygen) organic residues from plant or animal residues.

CARBON CANISTER

Activated carbon filters, unlike most filters that capture solid particles and create a differential pressure, are intended to remove liquid impurities.

The absorption of the molecules by the carbon does not cause a significant change in the differential pressure.

ACTIVATED CARBON CARTRIDGES

Activated carbon cartridges are designed to remove liquid impurities in gas treatments.

The absorption of the molecules by the carbon does not cause a significant change in the differential pressure.

The major impurities retained by coal are: Amine, Glycol, Water, Oli, Selexol, Sulfinol.

All charcoal filters contain 100% virgin granular activated carbon made from charcoal which undergoes a high temperature steam activation process.

This process maximizes the absorption zones for high and low molecular weight impurities.

sintered filters

Alongside the production of filter cartridges, to be close to customer needs, our company also offers pressure control devices for pilot plants and a wide range of sintered filters.

The latter are characterized by narrow tolerances, and by a wide range of stainless steel and bronze filters.

| TYPE | DIMENSIONS | FILTER SURFACE | WEIGHT | |||

| G | De. | Di. | h | H tot. | Cm² | Kg |

| 0,5 | 80 | 35 | 112 | 120 | 600 | 0,2 |

| 1 | 95 | 50 | 157 | 165 | 1.250 | 0,325 |

| 1,5 | 120 | 69 | 202 | 210 | 2.300 | 0,565 |

| 2 | 165 | 86 | 262 | 270 | 4.700 | 1,26 |

| 5/8” | 158 | 90 | 252 | 260 | 4.500 | 1,20 |

| 2,5 | 200 | 110 | 275 | 283 | 7.250 | 1,55 |

| 3 | 252 | 138 | 312 | 320 | 9.500 | 2,31 |

| 3,5 | 299 | 186 | 242 | 250 | 9.500 | 3,00 |

| 4 | 299 | 186 | 407 | 415 | 14.500 | 3,6 |

| 5 | 390 | 246 | 462 | 470 | 23.000 | 5,5 |

| 6 | 475 | 320 | 617 | 625 | 42.000 | 7,5 |

| 8 | 600 | 370 | 650 | 650 | 70.000 | 10,2 |

| 8 | 600 | 480 | 650 | 650 | 70.000 | 10,0 |

| In the table above, “h” refers to the height of the cartridge without seals. | ||||||

| TYPE | FILTER SURFACE (m²) | De (mm) | Di (mm) | Htot. (mm) |

| ZPZ 25 | 0,05 | 50 | 27 | 88 |

| ZPZ 50 | 0,14 | 80 | 54 | 155 |

| ZPZ 80 | 0,38 | 106 | 76 | 305 |

| ZPZ 100 | 0,52 | 130 | 105 | 377 |

| ZPZ 150 | 1,10 | 185 | 152 | 557 |

N.B. All the standard measures shown in the table can be modified according to the customer’s requests.

| TYPE | FILTER SURFACE (m²) | De. (mm) | Di (mm) | Htot.(mm) |

| VPZ 45/150 | 0,43 | 105 | 45 | 150 |

| VPZ 50/100 | 0,24 | 110 | 50 | 100 |

| VPZ 60/200 | 0,88 | 122 | 60 | 200 |

| VPZ 90/200 | 1,10 | 152 | 90 | 200 |

| VPZ 90/300 | 1,30 | 152 | 90 | 300 |

| VPZ 90/370 | 2,05 | 152 | 90 | 370 |

| VPZ 90/400 | 2,20 | 152 | 90 | 400 |

| VPZ 120/200 | 1,32 | 182 | 120 | 200 |

| VPZ 120/600 | 3,96 | 182 | 120 | 600 |

| VPZ 170/200 | 1,65 | 232 | 170 | 200 |

| VPZ 170/400 | 3,30 | 232 | 170 | 400 |

| VPZ 170/600 | 5,00 | 232 | 170 | 600 |

| VPZ 220/200 | 2,00 | 282 | 220 | 200 |

| VPZ 220/500 | 5,00 | 282 | 220 | 500 |

| VPZ 270/200 | 2,40 | 332 | 270 | 200 |

| VPZ 270/600 | 7,30 | 332 | 270 | 600 |

| VPZ 350/600 | 9,00 | 412 | 350 | 600 |

N.B. All the standard measures shown in the table can be modified according to the customer’s requests.

TFJ COALESCENT FILTER CARTRIDGES

FILTER MEDIA: Composite glass fiber with inert phenolic binders

INTERNAL PROTECTION: In perforated galvanized steel

BOTTOMS: In galvanized steel

GASKET: Buna N

EXTERNAL LINING: Cotton sock

mechanical characteristics

Differential pressure with clean filter: 0.05 bar

Differential pressure for cartridge change: 1 bar

Maximum working temperature: 130 ° C

Collapse pressure: 3.5 bar

ACTIVATED CARBON CARTRIDGES

Our cylindrical cartridges have a sturdy metal structure designed to contain the activated carbon in the form of cylinders. With adequate sizing, it also allows to eliminate odors coming from finishing plants and to comply with regulatory requirements.

Thanks to the sturdy galvanized sheet structure, this type of filter cartridges are designed for intensive use cycles.

It is a good idea to line the air inlet section of these activated carbon baskets with a custom made pre-filter.

| CODE | TYPE | FILTRATION | GASKETS | PROTECTIONS |

| TF | 4001 = De. 120 x Di. 80 x 350 H mm |

A B C |

S N V E |

BA SS ZA |

| 4002 = De. 120 x Di. 80 x 700 H mm | ||||

| 4003 = De. 120 x Di. 80 x 915 H mm | ||||

| 6002 = De. 170 x Di.110 x 915 H mm | ||||

| 8002 = De. 210 x Di. 155 x 915 H mm |

*FILTRATION : A = 3 micron B = 0,1 micron C = 0,01 micron

*GASKETS : S = Silicone N = Buna N V = Viton E = Epdm

*PROTECTIONS : BA = Martensitic steel SS = Steel 316L ZA = Galvanized iron

TF – TYPE – FILTRATION – GASKETS – PROTECTIONS

Es. TF – 4001 – A – S – BA

In our range of cartridges any model can be modified in size according to the needs of our customers.

It is the user’s responsibility to determine the suitability of the product required for a specific use and its adaptability to their own use procedures.

COALESCENT FILTER ELEMENTS

These cartridges have been designed to create a coalescence effect, the dirty gas passes through the filter element from the inside to the outside, the solid particles are retained inside the filter element thanks to a pre-filter while the liquid particles are agglomerated by the filtermedia. The force of gravity then makes them flow to the bottom of the vessel, where they are eliminated by purge valves.

Each of our products is rigorously checked during the processing stages and tested at the end of the production cycle, where the marking operation takes place for product identification and subsequent packaging.

The pleated filter media gives the cartridge a high filtering surface and a low pressure drop and consequently a longer operating period.

filtration code and technical data

| DESCRIPTION | TYPE | ||

| Degree of filtration | 3 micron | 0,1 micron | 0,01 micron |

| Operating temperature | Min. 1°C – Max 120°C | ||

| Steam residue | 5 mg/m3 | 0,1 mg/m3 | 0,01 mg/m3 |

| Δp filter (nominal flow) | 60 mbar max | 80 mbar max | 120 mbar max. |

| Direction of flow | From inside to outside | ||

| Max breaking pressure | 3 Bar | ||

| CODE | DE mm. | DI mm. | SP. mm. | PRESSURE LOSS Mbar / d= 0,8 Kg/m³ | DEGREE OF FILTRATION |

| AF DN25 | 70 | 32 | 4,1 | 5,2 (35 m³/h) | 100 MICRON |

| AF DN32 | 80 | 45 | 4,1 | 5,2 (50 m³/h) | 100 MICRON |

| AF DN40 | 90 | 50 | 4,1 | 6,6 (65 m³/h) | 100 MICRON |

| AF DN50 | 110 | 66 | 4,1 | 3,8 (100 m³/h) | 100 MICRON |

| AF DN65 | 120 | 80 | 4,1 | 3,4 (125 m³/h) | 100 MICRON |

| AF DN80 | 145 | 95 | 4,1 | 3,1 (160 m³/h) | 100 MICRON |

| AF DN100 | 163 | 115 | 4,1 | 4,6 (400 m³/h) | 100 MICRON |

| AF DN150 | 222 | 160 | 5,1 | 3,6 (1.000 m³/h) | 100 MICRON |

| AF DN200 | 270 | 208 | 5,1 | 3,5 (1.500 m³/h) | 100 MICRON |

| AF DN250 | 320 | 258 | 5,1 | 3,6 (2.200 m³/h) | 100 MICRON |

“GC” SERIES CARTRIDGES

These cartridges are used in cabins or cabinets to protect natural gas pressure reducers.

They have a filtering capacity from 0.1 to 50 microns according to customer requirements, and can be produced using various materials such as polyester felt, paper impregnated with resins, stainless steel or polyester.

Filters that mount this type of cartridges are produced with 1 “- 1” connections; 1/2 “- 2” threaded and with provision for in-line or square mounting.

These filters are “SEP” certified and can work up to operating pressures of 5 bar.

IMPREGNATED PAPER CARTRIDGES

These cartridges are made for medium pressure cabins, where the purification process of natural gas or hydrogen has already partly taken place.

They consist of a rot-proof and water-repellent filter media with a filtering surface equal to three times the standard with a filtration of 20 microns.

Their function is to protect membrane pressure reducers and measuring instruments placed in cabinets for mainly civil use.

STAINLESS STEEL REGENERABLE “G” UNIFIED SERIES CARTRIDGES

These cartridges have been developed to meet the customer’s needs to have a product that can be regenerated at the maintenance site of the gas plant, allowing to reduce the costs of spare parts.

The stainless steel cartridges, according to the customer’s request, can be produced with filtration degrees from 10 to 1,000 microns and can be reinforced with internal cages made of welded steel plates and immersed in the glue to withstand the very rigid conditions they have to endure.

These cartridges are washable with industrial detergents and water and after blowing they are immediately reused.

3 MICRON CARTRIDGES

They have a filtering capacity of 3 microns.

The cartridge obtains an external pre-filtration and a final internal filtration that allow a vast accumulation of dirt with a clogging of the cartridge that can be prolonged over time.

The cartridge is considerably reinforced in the structure for better resistance to mechanical stress.

5 MICRON “K” SERIES CARTRIDGES

These “K” series cartridges are used to protect natural gas regulation and measurement equipment from mechanical erosion of dust.

They have a filtering capacity of 5 microns (standard).

The filter fabric is BIA-USGC certified and is thermo-stabilized on the inlet side for better dust detachment.

0.5 AND 0.1 MICRON UNIFIED “G” SERIES CARTRIDGES

These cartridges have a very high filtering capacity and are used for the filtration of air or technical gases.

The multilayer that composes them makes them capable of stopping tiny solid particles down to 0.1 microns.

They are supported by adequate protections that guarantee high differential pressures.

To obtain efficient filtration, low speeds must be considered when designing the vessel to allow the fabrics to work at their best.

Furthermore these cartridges have coalescing power for the separation of oil / water from gas.

1 micron “G” unified SERIES CARTRIDGES

These new generation cartridges have a very high filtering efficiency and protect equipment such as gas turbines where dust that can damage the moving parts is not allowed.

The new generation fabrics, BIA-USGC certified, used in the construction, provide for a Teflon treatment of the filter media which ensures absolute resistance of the material to high temperatures, traction and cutting of the fabric, also giving it a valid coalescing power.

Appropriate shatterproof protections guarantee very high differential operating pressures.

5/20/50 MICRON CARTRIDGES

They have a filtering capacity of 5 microns (standard).

The filter fabric is BIA-USGC certified and is thermo-stabilized on the inlet side for better dust detachment.

Direction of filtration (standard) from outside to inside.

At the request of the customer when there are high pressure differences, the cartridge is internally armored with a reinforcement cage.

CARTRIDGES WITH WATER-REPELLENT TREATMENT

These new generation cartridges have a filtering efficiency of 5 microns.

The filtering fabric that composes them is impregnated in a chemical solution containing fluorinated resins and PTFE.

This treatment gives it protection from chemicals, acids, protection from hydrolysis, greater durability, the cartridge is made water-repellent and creates a coalescence effect that gives it better release thanks to the non-stick action.

disc filters

technical features

Support micro-stretched sheet in Aisi 316L

Filtration cloth of 100/300/1.000 micron in Aisi 316L. on customer request.

Non metallic part in asbestos free/aramid fiber with nbr legancy

Maximum working temperature 220°C

Temperature admitted for short periods: 330°C

vpz series cartridges

To allow efficient filtration of the biogas, the cellulose impregnated with resins and reinforced with polyester fibers is pleated to obtain a greater filtering surface and therefore a greater accumulation of particles. The filter media is supported both internally and externally by galvanized iron protections, they have been designed to provide the filter element with a flow surface compared to other types of materials.

These cartridges can be cleaned with low pressure compressed air in an emergency to make them reusable.

However, the pores of the filter will still be clogged with dirt particles, and the cartridge will still need to be replaced in the short term.

zpz series cartridges

To allow efficient filtration of the biogas, the cellulose impregnated with resins and reinforced with polyester fibers is pleated to obtain a greater filtering surface and therefore a greater accumulation of particles. The filter media is supported both internally and externally by galvanized iron protections, they have been designed to provide the filter element with a flow surface compared to other types of materials.

These cartridges can be cleaned with low pressure compressed air in an emergency to make them reusable.

However, the pores of the filter will still be clogged with dirt particles, and the cartridge will still need to be replaced in the short term.

FILTER CARTRIDGES FOR REFINED PETROLEUM PRODUCTS, CHEMICAL SOLVENTS AND SEA WATER

The filtration degrees vary according to the fluids to be treated with a range that goes from 5 to 2,000 microns. The cartridges have a height of 10 “(254 mm) – 20” (508 mm) – 30 “(762 mm) – 40” (1016 mm) standard. Each cartridge is studied together with the customer and can vary in size. They are available in pleated version or in smooth candle version.

Thanks to the materials they are made of, they can reach high operating temperatures while also guaranteeing excellent working differential pressures.

All these cartridges are washable and regenerable.

On request, different seals are supplied, for example: Buna N, Viton, Teflon etc.

On request, external protections are also supplied for greater mechanical resistance and to guarantee double internal – external flushing.

DEDUSTING CARTRIDGES

They are made with pleated filter media in cellulose impregnated with resins or in polyester.

These pleated cartridges offer a greater filtration surface ensuring a high filtering power and durability of the cartridge and thanks to their size and weight, they are easily installed and maintained.

The resistance to temperatures varies according to the filter media, we are talking about 120 ° C for paper impregnated with resins and 150 ° C for polyester.

Cartridge filters have proved to be suitable for treating:

plastic, epoxy, siliceous and metal powders; starchy and vegetable compounds, even wet

ceramics, talc and mineral compounds; cosmetic, pharmaceutical and chemical powders

sands and cements; smoke from laser cutting and / or welding

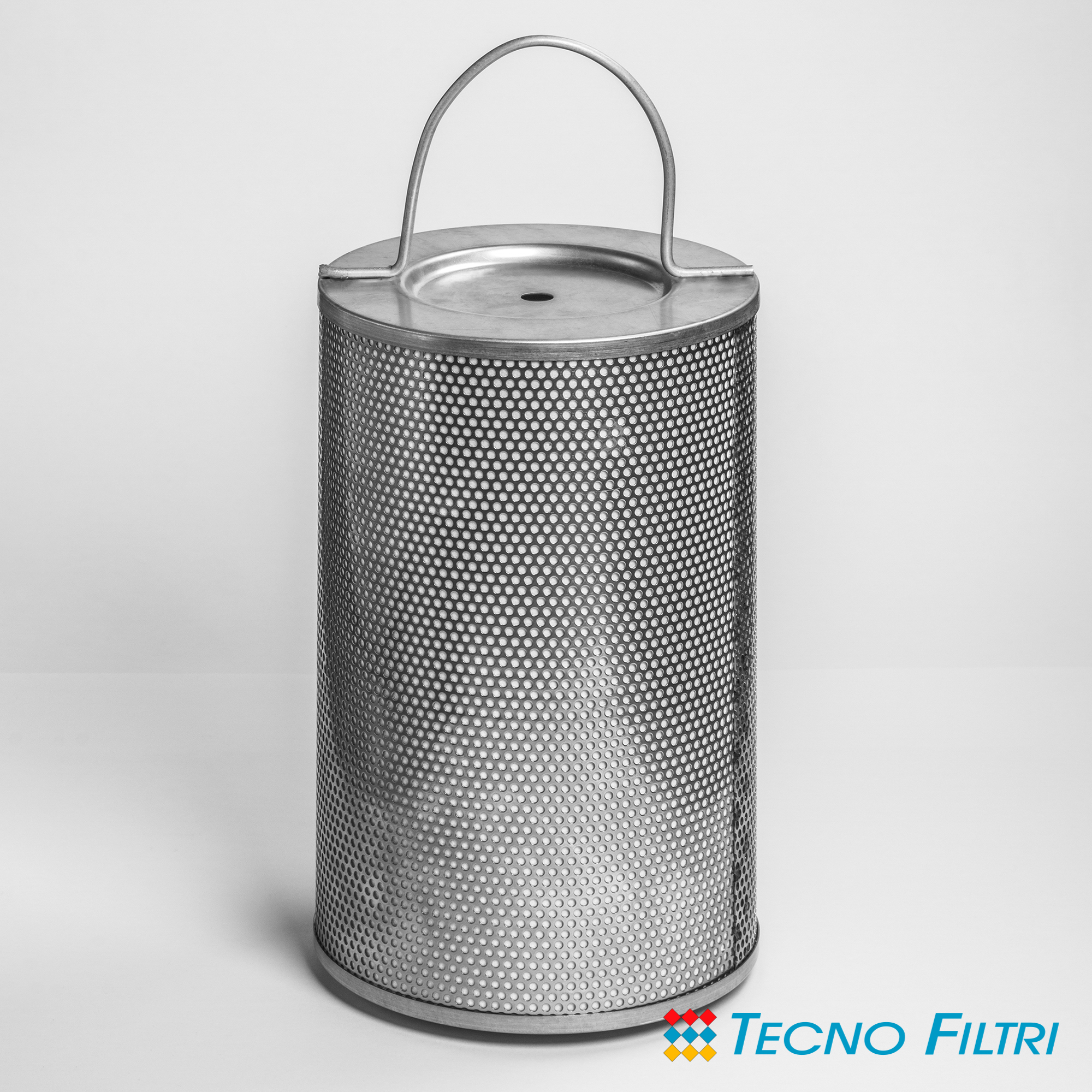

CARBON CANISTER

Activated carbon filters, unlike most filters that capture solid particles and create a differential pressure, are intended to remove liquid impurities. The absorption of the molecules by the carbon does not cause a significant change in the differential pressure.

The major impurities retained by coal are: Amine, Glycol, Water, Oli, Selexol, Sulfinol.

They are preceded by a pre-filter to stop solid particles that could compromise the efficiency and life of the carbon and it is usually recommended to also insert a filter downstream to keep the possible leakage of tiny particles of carbon. All charcoal filters contain 100% virgin granular activated carbon made from charcoal which undergoes a high temperature steam activation process. This process maximizes the absorption zones for high and low molecular weight impurities.

MATERIALS

| COAL | Granular activated carbon 8x30 mesh |

| INTERNAL AND EXTERNAL PROTECTION | Perforated sheet |

| INTERNAL AND EXTERNAL COVERAGE | cotton |

| BOTTOMS | Steel |

| GASKETS | Buna N |

| HANDLE | Stainless Steel |

The materials that compose them guarantee a maximum operating temperature of 150 ° and a flow rate (recommended) of 4.92 Ipm per carbon filter. Different models are built depending on the vessel in which they will be mounted (see button under the product photo).

| MODEL | De. (mm) | Di. (mm) | H tot. (mm) |

| 618-C | 159,0 | 66,7 | 464,0 |

| 636-C | 152,0 | 89,0 | 914,5 |

| 719-C | 184,0 | 57,2 | 489,0 |

| 720-C | 184,0 | 39,5 | 520,0 |

| 720-C1 | 184,0 | 57,2 | 520,0 |

| 722-C | 188,0 | 40,0 | 565,0 |

| 1120-C | 279,5 | 57,2 | 514,0 |

| 1122-C | 279,5 | 40,0 | 565,0 |

| 1122-C1 | 279,5 | 57,2 | 559,0 |

| 1122-C2 | 279,5 | 57,2 | 565,0 |

sintered bronze filters

Bronze filters are filter elements that have good resistance to sea water and can be used in the hydraulic field.

The bronze filters are obtained from a mixture of powders placed inside a mold, subsequently heated in a controlled atmosphere oven, by sintering.

sintered stainless steel filters

Sintered stainless steel filters are the ideal choice for applications and processes where high resistance to corrosion and high temperatures (up to 450 ° C) is required. Through the use of stainless steel it is possible to obtain filters with a maximum external diameter of 200 mm and a maximum length of 1,000 mm.

The molding takes place at room temperature, while the sintering process takes place at high temperatures in a neutral atmosphere.